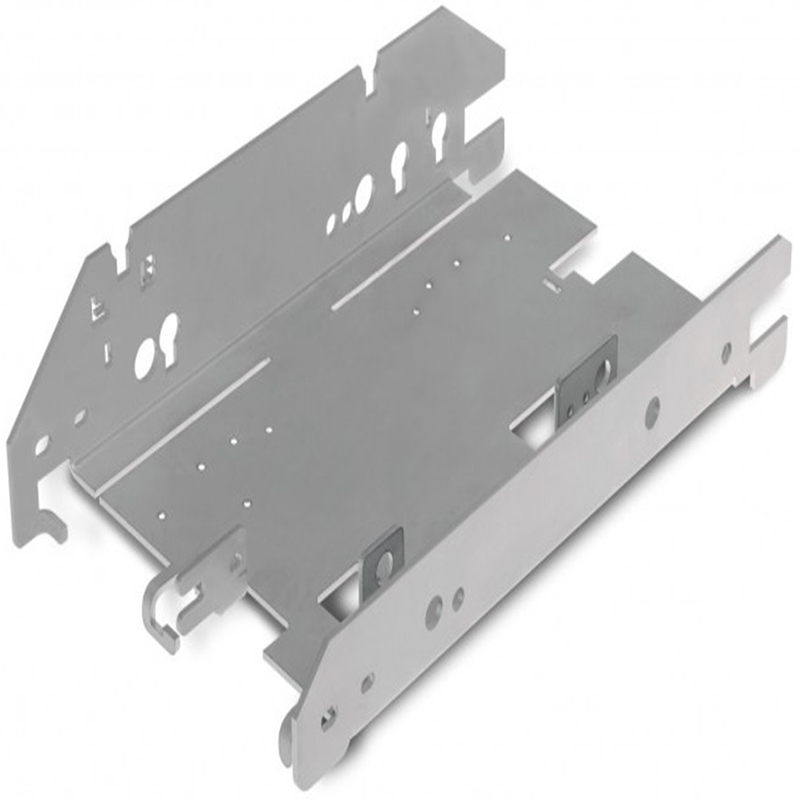

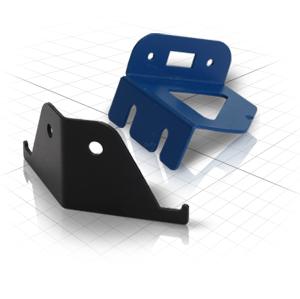

Laser Cutting Machining Punched Kobelang Welding Stamping Plate Parts

Laser e nepahetseng haholo e etsa mouoane mola o sehiloeng ka har'a letlapa la tšepe, e siea sekhahla sa boemo bo holimo ba 90-degree.Ho kobeha ka tšepeke ts'ebetso ea bohlokoa indastering ea tlhahiso, 'me ke phetoho ea polasetiki ea mosebetsi holim'a axis, e bakang phetoho ho geometry ea karolo.Ho tšoana le lits'ebetso tse ling tsa ho etsa tšepe, ho khumama ho fetola sebopeho sa karolo ea mosebetsi, ha boholo ba thepa bo tla lula bo tšoana.Ka linako tse ling theknoloji e kobehae ka tlisa phetoho e nyane ka botenya ba lakane.Bakeng sa lits'ebetso tse ngata, ha e na ho hlahisa phetoho botenya.Ntle le ho theha sebopeho sa geometri se lakatsehang, ho kobeha ho sebelisoa ho fana ka matla le ho satalla ho lakane ea tšepe, ho fetola motsotso oa karolo ea inertia, bakeng sa ponahalo ea litlolo le ho felisa likarolo tse bohale.Tlhahiso ea likarolo tsa tšepe ea prototyping e na le ho bopa letlapa la tšepe (lisebelisoa tse phuthoang tse fumanoeng ka laser ho itšeha) ho e fa sebopeho le ponahalo e lakatsehang.Re etsa mesebetsi e fapaneng ea ho etsa sebopeho le ho mena, ho phunya, ho hatakela le ho kopanya ka ho tjheseletsa.Ho ka sebelisoa liphetho tse fapaneng tse fapaneng (ho penta, anodizing, joalo-joalo).Tšebeliso ea mekhoa ena e fapaneng e itšetlehile ka thepa e khethiloeng, botenya ba lakane e sebelisitsoeng (ho ea ka ts'ebeliso e lakatsehang ea li-prototypes tsa hau kapa lihlopha tse nyenyane) le sebopeho se khethiloeng.

Lihlopha tsa lihlahisoa

-

Mohala

-

E-mail

-

Whatsapp

whatsapp

-

WeChat

-

Holimo